MES and Industrial IoT

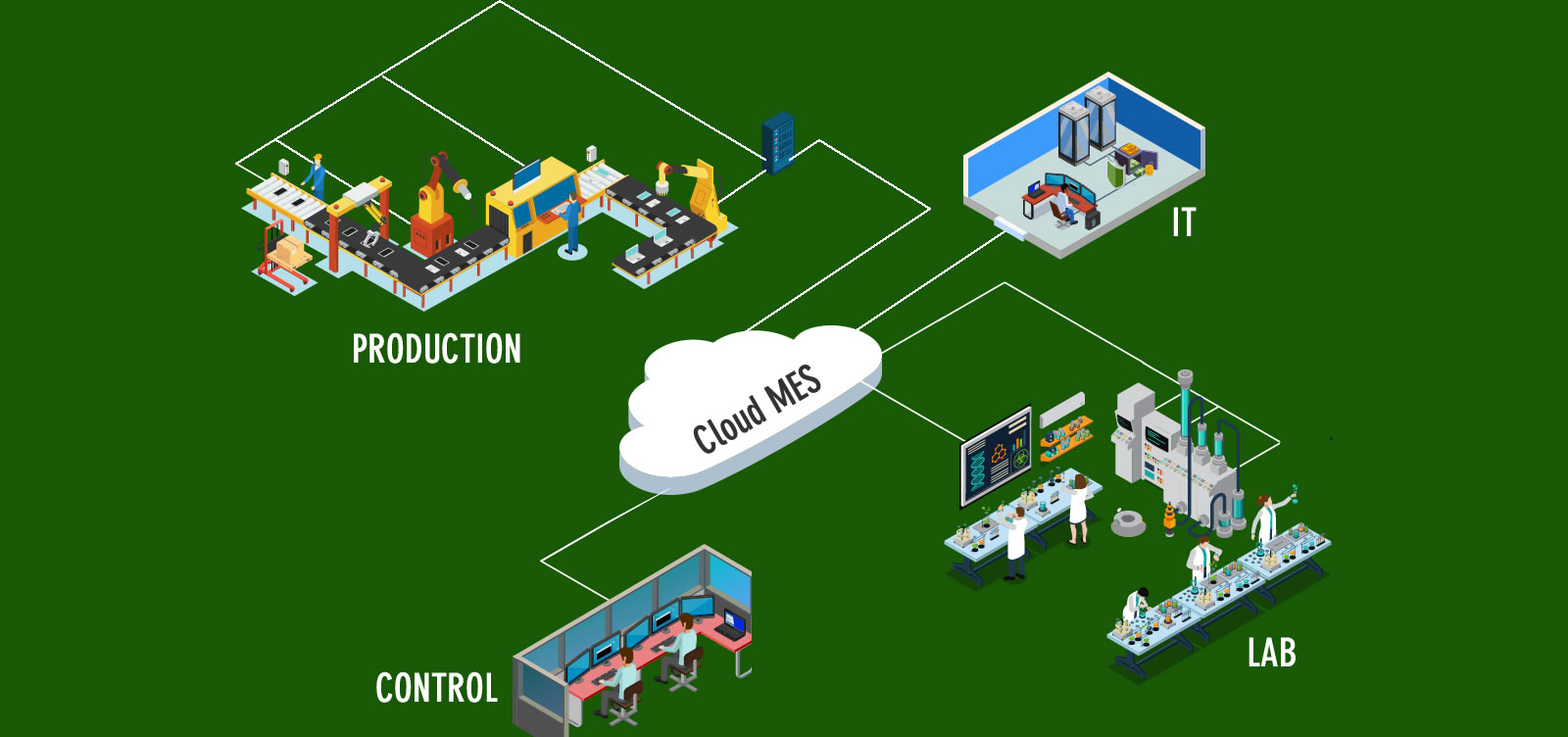

The Internet of Things (IoT), in short, is the concept of connecting any kind of device with an electronic interface to another device with an electronic interface. These devices, being wireless or wired, are connected to each other using the Internet. A special class of IoT is that of Industrial Internet of Things (IIot). In fact, IIoT is an evolution of a Distributed Control System (DCS) that allows for a higher degree of automation by using cloud computing to refine and optimize process controls. A state of the art Manufacturing Execution System (MES) is able to connect to any systems in the Cloud and therefore also to any Industrial IoT. In case a MES itself runs in the Cloud using Cloud Computing, it is called a Cloud MES.

Private Cloud

Cloud Computing implies the on-demand delivery of compute power, database storage, applications, and other IT resources through a Cloud services platform via the internet. Examples of large Cloud service platforms are Amazon Web Services (AWS) and Microsoft Azure. Important benefits of Cloud Computing are:

- No need for purchase and maintenance of in-house servers;

- Much easier to scale both up and down the required computing power and storage;

- Easier to setup one or more Virtual Networks for accessing, controlling and integrating different systems and devices including Industrial IOT, MES, ERP, and other internal or external systems.

Cloud Computing used for Industrial production, normally resides inside a Private Cloud. The difference between a Public Cloud and a Private Cloud is that in a Private Cloud, strict access controls are in place, regulating who and what has access to the networked services, storage and devices in the own Private Cloud. In fact, access to such a Virtual Network is only granted to valid public-private keypair holders and/or users and systems accessing the network from registered IP addresses. Strong firewalls are in place to prevent unauthorized access.

MES software can be run on a virtual server in the Private Cloud. Making it very simple to scale up and down the required computing power and storage matching any changes in the size and activities of the company. The Virtual Network in the Private Cloud is used to connect all Industrial IoT devices to it. Making it relative simple to interconnect these devices to each other and to connect these devices to Middleware, SCADA systems and to the MES. As such, it becomes less relevant whether any of these devices and systems are in the same location or in a location on the other side of the world.

Middleware

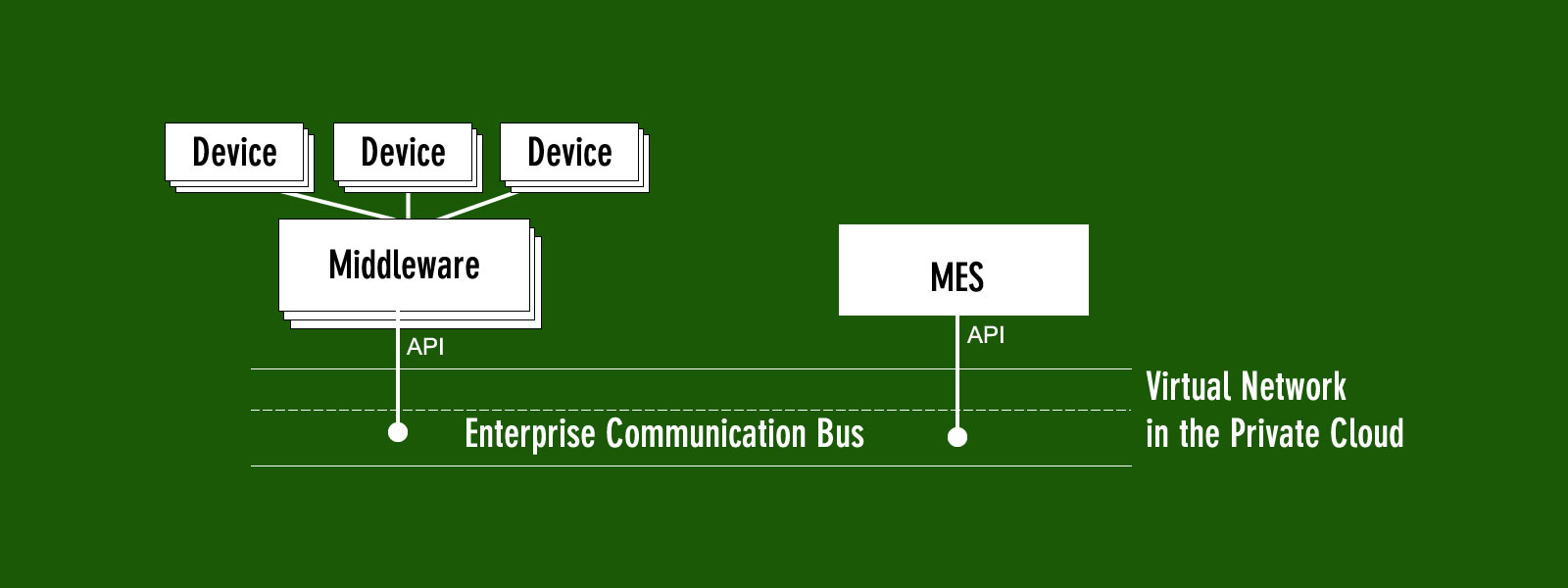

Industrial devices, that allow access and control via a network interface, often use proprietary/legacy protocols. Resulting in a very heterogeneous landscape where it is often difficult to find a manageable solution to connect all these devices via a Virtual Network to each other and to other systems. Middleware systems are likely the best solution to make such a heterogeneous landscape more manageable. They provide the means to setup a standardized communication bus (referred to as an Enterprise Communication Bus) to which existing devices can be connected. To make this possible, Middleware systems contain a large collection of libraries and configurable plugins for "plug-and-play" connections to all industrial devices of popular brands. In such a setup, a MES does not connect directly to a specific device but does this so via connecting over the Enterprise Communication Bus to the Middleware systems. This is done via a standardized Middleware API and Webhooks. The Middleware takes care of the translation to and from the propriate/legacy protocols of specific brand industrial devices. In case the Middleware contains a Message Broker, it will use the Enterprise Communication Bus to actively send messages to subscribers, notifying them about any changes. In case a Private Cloud is used, the carrier of the Enterprise Communication Bus would be the Virtual Network, running over the Internet.

EZ-MES in private cloud

EZ-MES is a real-time browser based Manufacturing Execution System that can run both on premises as well within a Virtual Private Network and making use of Cloud Computing. EZ-MES comes with an Open API and Webhooks, allowing it to connect to other systems and devices. It is also possible to connect EZ-MES to several Middleware systems, allowing it to connect to a wide scope of existing industrial devices and equipment. As such, EZ-MES fits frictionless in a world with Industrial Internet of Things.

The following video demonstrates the use of the EZ-MES API to interface over a Private Network with a middleware layer, in this case Node-RED. By doing so, EZ-MES can be used to fully track equipment measurements in production processes. In this demonstration, EZ-MES is used to track an Oven temperature via Node-RED during a simplified production process.